The Relevance of an Optical Measurement System in Industrial Applications

Optical measurement systems play a critical role in commercial applications. They offer high accuracy and promote non-contact measurement, which is crucial for shielding delicate elements. These systems boost operational effectiveness and advertise high quality control. Nonetheless, their application is not without challenges. Comprehending their relevance and the intricacies entailed can brighten their transformative potential in modern-day manufacturing. What are the certain benefits and difficulties that these systems present?

Comprehending Optical Measurement Systems

Optical measurement systems play a necessary role in different commercial applications by providing specific and exact information collection. These systems make use of light to gauge physical residential properties such as dimensions, surface accounts, and product attributes. The fundamental components normally include lasers, cams, and sensors that record and analyze light mirrored from things. By employing techniques such as interferometry and photogrammetry, these systems can discover minute changes in form and size, which are critical for high quality control and item consistency.Furthermore, optical measurement systems are non-contact, permitting them to examine fragile or elaborate products without creating damage. They are flexible, locating applications in fields like aerospace, auto, and electronic devices manufacturing. The combination of innovative software for information evaluation enhances the performance of these systems, making it possible for real-time tracking and responses. As markets develop, the relevance of optical measurement systems continues to grow, supporting the demand for greater precision and efficiency.

Trick Advantages of Optical Measurement in Manufacturing

While traditional measurement approaches usually include physical get in touch with and can present mistakes, the fostering of optical measurement systems in manufacturing deals considerable benefits. These systems make use of non-contact methods, reducing the danger of damage to sensitive components and making sure the stability of dimensions. Optical measurement supplies high accuracy and accuracy, making it possible for suppliers to attain tight resistances vital in affordable markets.Additionally, the rate of optical measurement systems enhances performance. optical fibre diameter analyser. Rapid data acquisition permits real-time surveillance, facilitating prompt adjustments in production processes. This efficiency brings about minimized waste and improved source allocation.Furthermore, the convenience of optical systems suits a large range of products and geometries, making them appropriate for numerous applications. Their ability to integrate perfectly with automation technologies supports Sector 4.0 campaigns, promoting smarter producing atmospheres. On the whole, the vital benefits of optical measurement contribute considerably to enhancing quality control and functional efficiency in modern-day production settings

Applications of Optical Measurement Equipments

Optical measurement systems play an essential function in various commercial applications, particularly in enhancing accuracy during manufacturing processes. They are integral to high quality control and guarantee, making certain that products meet strict criteria. In addition, these systems support research and advancement efforts by supplying precise data for development and renovation.

Precision in Manufacturing Processes

In modern manufacturing, high precision is necessary for guaranteeing product high quality and functional performance. Optical measurement systems give innovative capacities that greatly boost precision throughout the production procedure. These systems utilize light and imaging modern technologies to catch detailed dimensions of components, making it possible for suppliers to achieve tight resistances and exact dimensions. By integrating optical measurement into production workflows, companies can quickly identify discrepancies from specifications, consequently reducing waste and minimizing rework. The non-contact nature of optical dimensions permits for examining delicate or delicate products without danger of damage. Eventually, the fostering of optical measurement systems promotes a culture of precision in manufacturing, bring about enhanced efficiency and competition in the market.

Quality Control and Guarantee

Quality assurance in making greatly relies on accurate measurement methods to guarantee that items satisfy well-known criteria. Optical measurement systems play a crucial function in this process, allowing accurate analyses of dimensions, surface top quality, and various other vital attributes of produced goods. By employing high-resolution imaging and innovative evaluation algorithms, these systems find discrepancies from specifications, ensuring uniformity throughout manufacturing. Additionally, optical measurements can be non-destructive, protecting the honesty of products while helping with quick assessments. The assimilation of these systems right into top quality control protocols improves performance and minimizes waste, eventually contributing to enhanced item reliability. As sectors endeavor for quality, the adoption of optical measurement modern technologies comes to be progressively essential for preserving affordable advantage and consumer fulfillment.

Research Study and Development Applications

As sectors venture for development, optical measurement systems have arised as a crucial device in study and development applications. fibre testing equipment. These sophisticated systems supply exact dimensions of materials and parts, making it possible for designers and researchers to obtain essential understandings into their buildings and efficiency. Optical measurement technologies, such as laser scanning and interferometry, assist in the fast prototyping of new layouts and the optimization of existing products. By capturing high-resolution information, researchers can determine flaws and analyze the effect of numerous criteria on item performance. In addition, these systems sustain interdisciplinary collaboration, linking voids in between different disciplines. The combination of optical measurement systems right into R&D processes inevitably increases advancement timelines and fosters the creation of innovative services in numerous industrial industries

Contrasting Optical Measurement to Conventional Methods

In contrasting optical measurement systems to conventional approaches, a number of key factors arise, including accuracy and precision. Additionally, the speed of measurement and cost-effectiveness play considerable functions in establishing the suitability of each approach for commercial applications. This examination highlights just how developments in optical innovation might provide advantages over traditional strategies.

Accuracy and Accuracy

Optical measurement systems supply substantial advantages in precision and accuracy contrasted to standard measurement methods. These systems use advanced innovation, such as lasers and high-resolution cameras, to record dimensional information with minimal error. In comparison, typical approaches typically count on mechanical tools that can introduce irregularity due to human mistake or product wear. Optical systems can accomplish micrometer-level accuracy, ensuring constant outcomes also in complex geometries. Furthermore, they give non-contact measurement, lowering the risk of damaging sensitive components. This ability is especially valuable in industries where tolerances are vital, such as aerospace and auto production. As a result, the adoption of optical measurement innovation enhances top quality control and lowers the possibility of problems, inevitably boosting general manufacturing efficiency.

Rate of Measurement

The benefits of optical measurement systems expand past precision and precision to consist of significant enhancements in measurement rate. Conventional measurement techniques commonly require extensive arrangements and hand-operated calculations, which can slow down production processes. On the other hand, optical systems use advanced technologies such as laser scanning and imaging, enabling quick data procurement and handling. This effectiveness enables real-time dimensions, promoting quicker decision-making in manufacturing environments. The capability to catch big volumes of data in a brief time enhances throughput and productivity, providing organizations an one-upmanship. In addition, with decreased measurement times, optical systems minimize downtime associated with inspections, even more enhancing operations. Subsequently, the speed of measurement in optical systems considerably adds to overall functional performance in industrial applications.

Cost-Effectiveness Evaluation

An extensive cost-effectiveness evaluation reveals that optical measurement systems frequently give considerable economic advantages over standard methods. These systems normally reduce the demand for considerable physical setups, lessening labor costs and downtime throughout measurement procedures. Optical methods can additionally generate faster outcomes, bring about increased efficiency and lowered functional expenditures. In addition, the accuracy provided by optical dimensions lowers the chance of pricey errors, which can develop from manual interventions and Continued typical methods. Over time, the preliminary investment in optical innovation is typically countered by cost savings in resources, time, and improved product high quality. Consequently, sectors that adopt optical measurement systems might find themselves not only improving efficiency but likewise accomplishing a much more desirable cost-benefit proportion contrasted to traditional techniques.

.png)

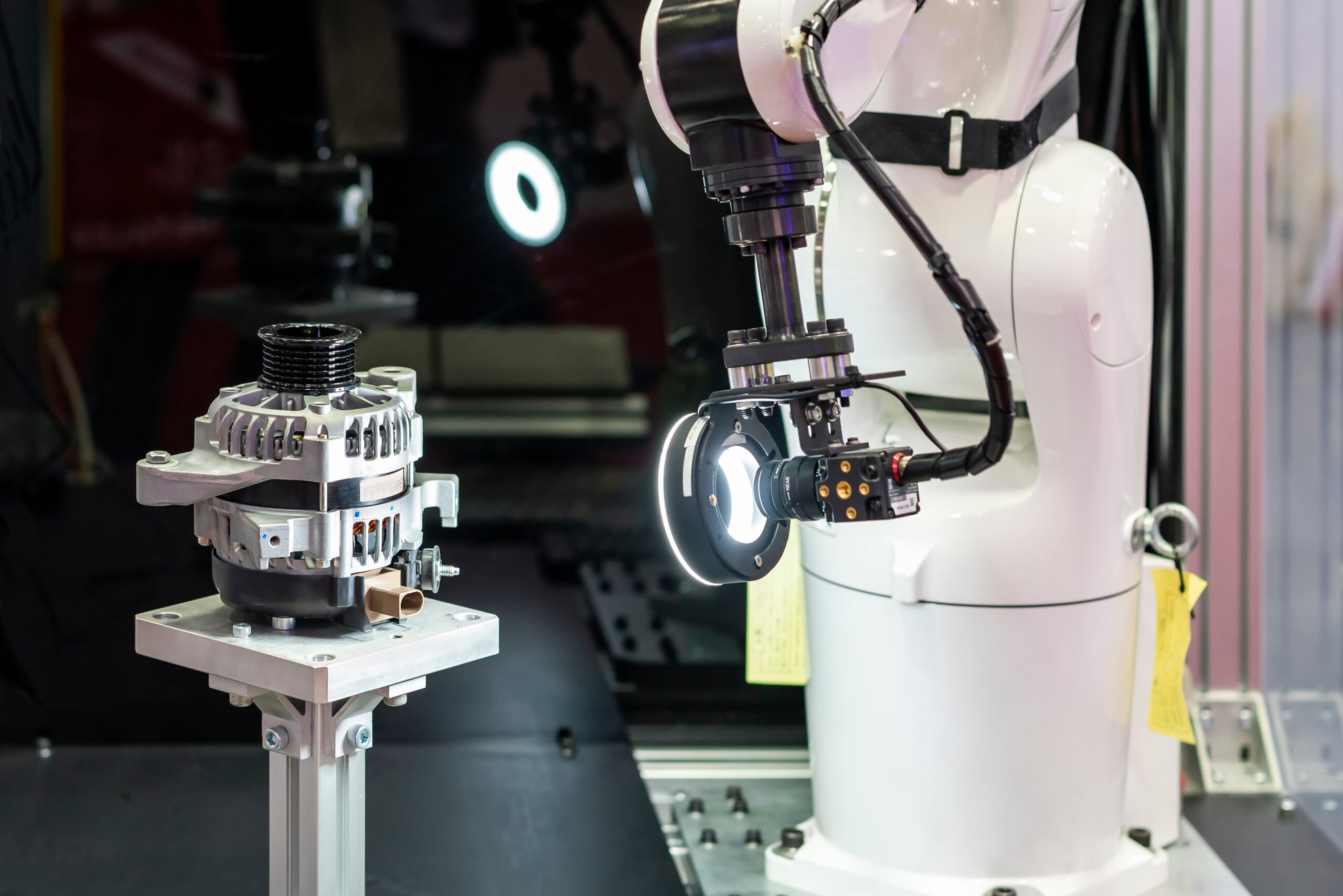

The Duty of Automation in Optical Measurement

While numerous sectors increasingly rely on precision and efficiency, automation has actually emerged as an important component in improving optical measurement processes. By integrating automated systems, companies can significantly boost measurement accuracy and minimize human error. Automated optical measurement systems use innovative formulas and sensing units to offer real-time information analysis, assisting in quicker decision-making and procedure adjustments.Additionally, automation enables regular i thought about this dimensions throughout various manufacturing runs, ensuring that high quality criteria are maintained. The scalability of automated optical measurement systems makes them appropriate for varied applications, from high quality control in producing to inspection in semiconductor production.Furthermore, these systems can be effortlessly incorporated right into existing manufacturing configurations, advertising a smooth shift towards a lot more reliable operations. In general, the function of automation in optical measurement is pivotal, providing improved integrity, reduced labor expenses, and enhanced functional performance, inevitably driving commercial competitiveness.

Obstacles and Considerations in Implementation

Implementing optical measurement systems, despite having the advantages of automation, provides various challenges and factors to consider that organizations should navigate. One substantial difficulty is the assimilation of these systems right into existing operations, which may require substantial changes in processes and employee training. Organizations must additionally resolve the compatibility of optical measurement technologies with current tools and software.Additionally, the irregularity of products and environmental conditions can impact measurement accuracy, requiring durable calibration and maintenance procedures. Cost is one more vital consideration, as first financial investments can be considerable, and organizations have to consider these costs against possible performance gains. Data management additionally presents difficulties, as the volume of details produced requires reliable systems for storage, evaluation, and analysis. Finally, making sure conformity with industry requirements and regulations includes another layer of intricacy to the execution procedure, needing mindful preparation and execution.

Future Fads in Optical Measurement Innovation

As sectors remain to progress, developments in optical measurement modern technology are set to change their operational landscapes. Arising patterns show a shift towards increased automation and combination with expert system, enhancing the accuracy and efficiency of measurements. Flexible optics is gaining traction, permitting systems to straight from the source adjust in real-time to varying ecological conditions, consequently decreasing errors. In addition, the miniaturization of optical sensors is enabling their implementation in much more portable and diverse settings, increasing application chances in markets such as aerospace and manufacturing.Additionally, the advancement of 3D optical measurement strategies is revolutionizing quality assurance procedures, using even more comprehensive data analysis. Advancements in data processing formulas are additionally anticipated to streamline the analysis of intricate measurements, making understandings a lot more easily accessible. Jointly, these patterns reflect a future where optical measurement technology not just improves accuracy yet also boosts operational agility, positioning sectors to better fulfill advancing needs.

Often Asked Inquiries

Just How Do Optical Measurement Solutions Ensure Data Accuracy?

Optical measurement systems assure data accuracy through exact calibration, progressed formulas, and high-resolution imaging. These elements collaborate to reduce mistakes, boost measurement uniformity, and give reliable outcomes necessary for different commercial applications and processes.

What Is the Regular Life Expectancy of an Optical Measurement System?

The common life expectancy of an optical measurement system differs, commonly varying from 5 to fifteen years. Elements affecting long life include use strength, environmental problems, upkeep methods, and technical developments that might demand upgrades or substitutes.

Can Optical Measurement Solutions Be Personalized for Particular Industries?

What Training Is Required for Running Optical Measurement Solutions?

Training for operating optical measurement systems generally includes understanding system parts, software program use, calibration methods, data evaluation, and security procedures. Participants frequently engage in hands-on technique and may complete accreditation programs to improve their proficiency.

How Do Ecological Aspects Affect Optical Measurement Outcomes?

Ecological aspects, such as temperature, humidity, and lights problems, considerably affect optical measurement outcomes. Variations in these elements can cause inaccuracies, affecting the accuracy and dependability of dimensions taken by optical systems in various setups.